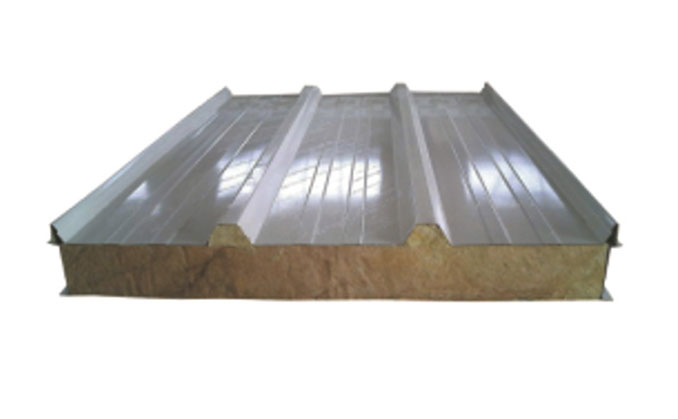

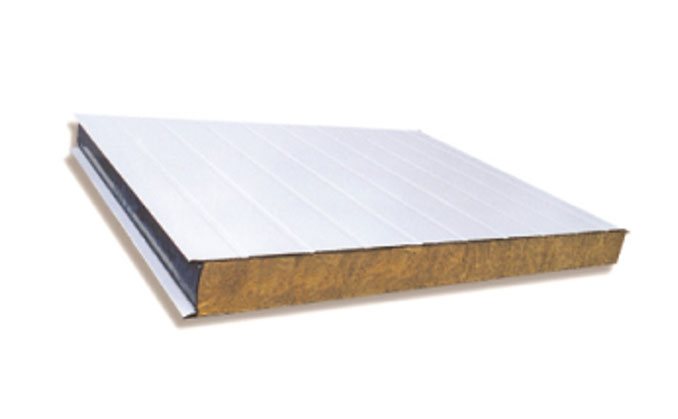

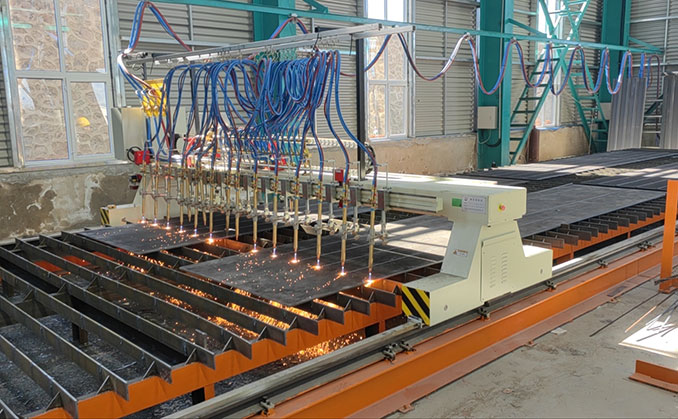

Rock wool sandwich panel are made of vertical filamentary rock wool as the core material and colored steel plate as the surface layer. They are formed by pressing with an automated continuous forming machine and then bonding with a high-strength adhesive. Since both the colored steel plate and the core rock wool are non-combustible, they have excellent fire resistance.

Parameter

Rock wool sandwich panel for roofing

Thickness(mm) | 75 | 100 | 120 | 150 |

Length(mm) | No length limit, limited by transportation conditions, generally ≤12000 | |||

Weight(KN/m²) | 0.263 | 0.301 | 0.338 | 0.391 |

Rock wool sandwich panel for wall Panels

Thickness(mm) | 50 | 75 | 100 | 120 | 150 | 200 |

Width(mm) | 1150 | 1150 | 1150 | 1150 | 1150 | |

Length(mm) | No length limit, limited by transportation conditions, generally ≤12000 | |||||

Weight(KN/m²) | 0.178 | 0.212 | 0.236 | 0.261 | 0.289 | 0.352 |

Rock wool sandwich panel for roofing

Thickness(mm) | 75 | 100 | 120 | 150 |

Length(mm) | No length limit, limited by transportation conditions, generally ≤12000 | |||

Weight(KN/m²) | 0.263 | 0.301 | 0.338 | 0.391 |

Rock wool sandwich panel for wall Panels

Thickness(mm) | 50 | 75 | 100 | 120 | 150 | 200 |

Width(mm) | 1150 | 1150 | 1150 | 1150 | 1150 | |

Length(mm) | No length limit, limited by transportation conditions, generally ≤12000 | |||||

Weight(KN/m²) | 0.178 | 0.212 | 0.236 | 0.261 | 0.289 | 0.352 |